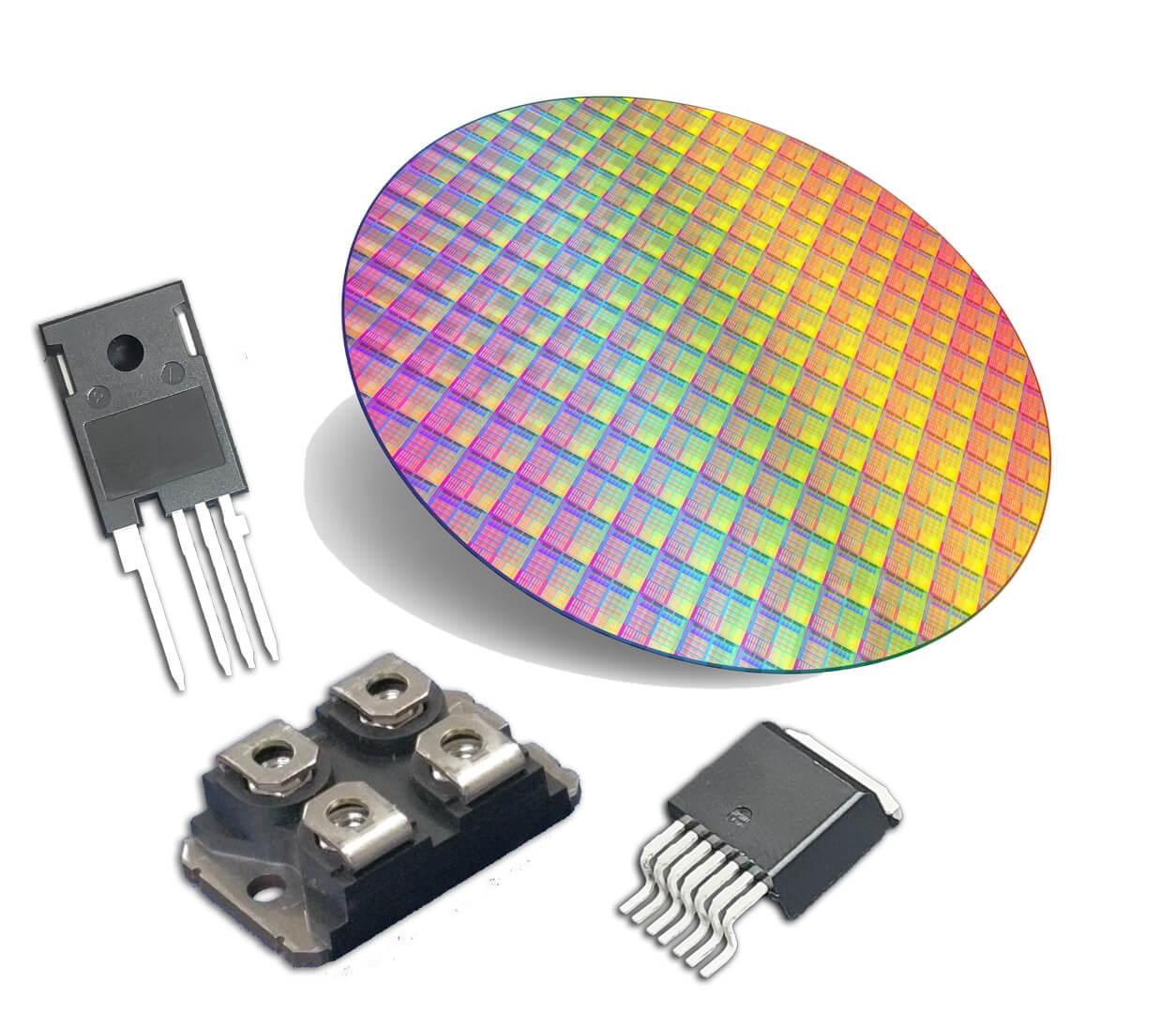

Since 2015, Fastech has prioritized the assembly and testing of silicon carbide (SiC) discrete devices, laying the foundation for robust and innovative process capabilities. Our ongoing dedication to enhancing and discovering efficient processing methods has facilitated faster time-to-market, improved yields, and reduced overall costs for our customers. Presently, seven companies trust Fastech for their SiC product assembly and testing needs. In the coming year, we are excited to expand our services to include power module packaging, further strengthening our commitment to delivering exceptional solutions in the power semiconductor packaging space.

A critical process that can affect yield, Fastech has developed custom recipes to achieve optimal results in yield, cost, and process throughput. To date we have sawn over 15,000 SiC wafers of varying physical characteristics.

- Optimized parameters for cutting rpm, feed rate, torque, and coolant.

- Material technology on blade size, thickness, and diamond abrasives.

- Design rule for wafer thickness (~100 um ~ 381 um), street width (down to 58 um) and material morphology.

Fastech provides a variety of die attach technology options tailored to suit the specific application, performance requirements, and cost objectives of SiC devices.

| Die Attach Material and Process | Performance- Solder Voids | Cost-Material | Cost-Process | Process Throughput |

|---|---|---|---|---|

| Soft Solder - Standard (spank) | <10% | Low | Low | Mid |

| Soft Solder - Next Gen (write) | <10% | Low | Mid-High | Mid-High |

| Pre-form Solder (VLO) | <5% | Mid | High | Low |

| Ag Sintered Epoxy | <1% | High | Low | High |

As SiC discrete devices are designed to operate at higher junction temperatures, the demand for encapsulants with correspondingly higher glass transition temperatures has emerged. Fastech has successfully qualified new molding compounds that meet stringent AEC Q101 certifications*¹ for our line of discrete packages. We provide a range of compounds for:

- Standard applications Tj of 125 degrees C

- Enhanced applications (i.e. automotive) Tj 175 degrees C

The emergence of SiC devices has necessitated testing capabilities for higher voltages and currents. Fastech offers test platforms equipped with a wide range of options and combinations for standard DC, high voltage, high current, delta, and unclamped inductive load (UIL) tests, available in both single and multi-pass configurations. Additionally, we are actively developing AC testing capabilities for power modules. Our current testing capabilities include:

| Standard DC Test | 20A/1000V | Delta | 50A/200V/300us-9.99s |

| High Voltage | 10mA/3.6KV | Unclamped Inductive Load | 200A/2500V/0.01-159.9mH |

| High Current | 200A/25V | 100A/3600V/1mH,5mH,10mH,20mH(3x) |

Available and currently in volume production for SiC devices are JEDEC TO247, TO220, TO263 and SOT227 with various lead configurations and substrate options. (See our package offering). For power modules, engineering evaluation and prototypes of FASTPAK 1, 2 & 3 are now available with substrate option for Al203 AIN and SI3N4 either in DBC or AMB (equivalent to EASYPACK/ACEPACK 1 & 2).

I. Three customers qualified on TO 247 4L 1200V SiC MOSFET, TO 263 7L 1200V SiC MOSFET and TO247 3L 650V GaNFET.